High Tech Innovation

Harmony Monitoring Instruments LLC is a female & veteran owned small business established to manufacture innovative, high quality medical devices. Our MLE Sensor addresses the need to use electronics to automate the routine task of monitoring the levels of fluids utilized during endoscopic surgeries and postoperative continuous bladder irrigation ( CBI ). Our design inputs come from an entire O.R. team of surgeons, nurses and surgical technologists.

Our MLE Sensor is made to enhance patient safety, improve patient care and it does so at an exceptional value. We manufacture our products to perform to the highest standards of safety and effectiveness. Our designs are elegant, easy to use and are built to last without ongoing costs. Our business aims to innovate technology that improves patient care while enhancing the efficiency and affordability of the healthcare systems that deploy them.

Features

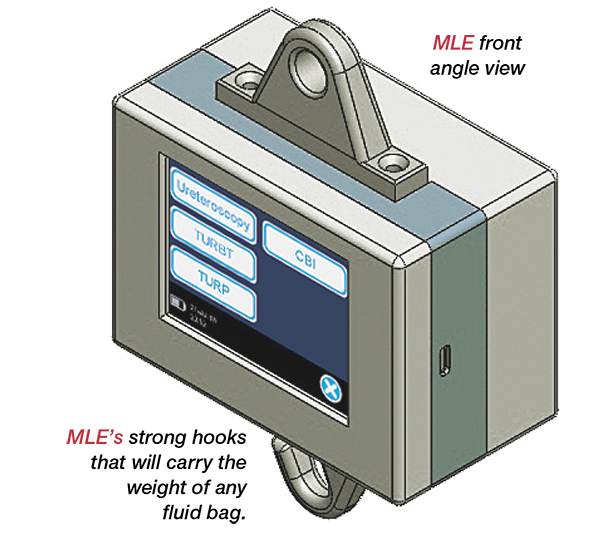

- Audible and visual alarm thresholds are easily set by TFT touch screen display this unique “set and forget” feature makes this device simple and easy to use.

- Helps to improve job satisfaction and efficiency of

healthcare workers. - Device system flashes as fluid level drops below the set threshold. The screen display indicates amount of fluid remaining, alarm threshold settings, time remaining until empty and other messages as appropriate.

- Audible alarm gently gets attention when fluids warrant without being overly distracting. The MLE device is built of durable thermoplastic material and is designed for reliability in everyday hospital handling conditions.

- The suspension hook will not fall off of IV pole with twisting, or pulling from the side.

- The lower hook is designed for easy bag placement and removal.

The Monitored Liquid Electronics

For premarket evaluation and informational purposes only. Call (562) 833-0242 for more details.

Streamline Your Supply Chain & Reduce Waste

The MLE Sensor will pay for itself in several ways.

• Enhances efficiency • Eliminates post TURP / TURBT Complications • Eliminates readmissions to the operating room

• Prevents staff fatigue.

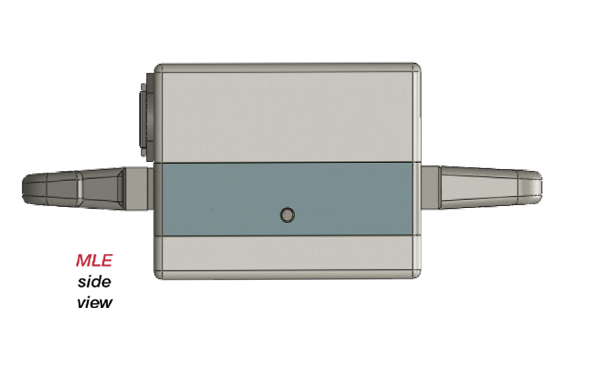

The MLE Sensor allows healthcare personnel to devote more energy to other tasks and can be wirelessly connected to the hospital supply chain. The MLE Sensor works reliably and accurately with any size of IV, or Irrigation fluid bag. Eliminates the need for using a 3000ml irrigation bag when all that is needed is a 1000ml bag. Less waste equals a guaranteed return on investment. It’s better for the environment too.

MLE was designed to be ecofriendly and energy efficient. We also adhered to the principle that our device should not trap the customer into having to pay an ongoing cost of expensive disposables. We purposefully designed our device to use generic, low cost AA batteries.

The MLE Sensor has built in electronic and software fail safes coupled with onboard memory and backup battery should the

primary batteries need replacing during a long surgical case or period of patient fluid treatment.

The Monitored Liquid Electronics Sensor

The MLE sensor is designed specifically to take the worry out of constant visual monitoring of IV drip, or irrigation fluid bags. It’s design is simple, reliable and affordable. The MLE is specifically designed to prevent surgical fluid bags from running dry.

A passive non-intelligent sensor could never monitor all the complex variations of applications found throughout the healthcare delivery system. Our MLE does and is truly a “smart sensor!” Finally, frontline healthcare workers are liberated from the constant need to visually monitor the fluids used to treat patients. Our MLE Sensor is the permanent solution to one of the most frequent causes of patient care disruptions.